Deployed in 2024

Smart Warehouse Fulfillment System

1 million

Hours saved for client's workforce

11

Global facilities managed with the new system`

Collaboration

Design Agency

Role

Project Lead

Product Designer

UX Researcher

Team

Visual Designer

PM

Stakeholder

CEO

SVP of IT

Backend Engineer

Platform

Mobile App, Dashboard

Duration

2023-2024

Business Challenge

In logistics, every second counts.

But the scattered data was causing delays

User Pain Point

Staff spent time hunting for data across complex interfaces — They need instant visibility to act fast

THE SOLUTION

Instant clarity on tasks, capacity, and delays for staff — powered by redesign

Dynamic Layout surfaces alerts instantly — no scanning, no searching

Dual-Mode Display adapts to complex lighting — from bright docks to dark aisles

Impact

I successfully increased efficiency at global scale

Hours saved for client's workforce

Global facilities managed with the new system`

Stakeholder teams onboarded

"The redesigned system dramatically improved our coordination and efficiency."

Claire Hung

Product Manager, ALP

Full Story

Research

I visited warehouse floors to uncover real problems

Workflow observations

Contextual interviews

System usability audits

Insights

I uncovered two critical issues

Critical data spread across 7 app screens

Dashboards unreadable from working distance

Key Feature 1

Everything critical in one view

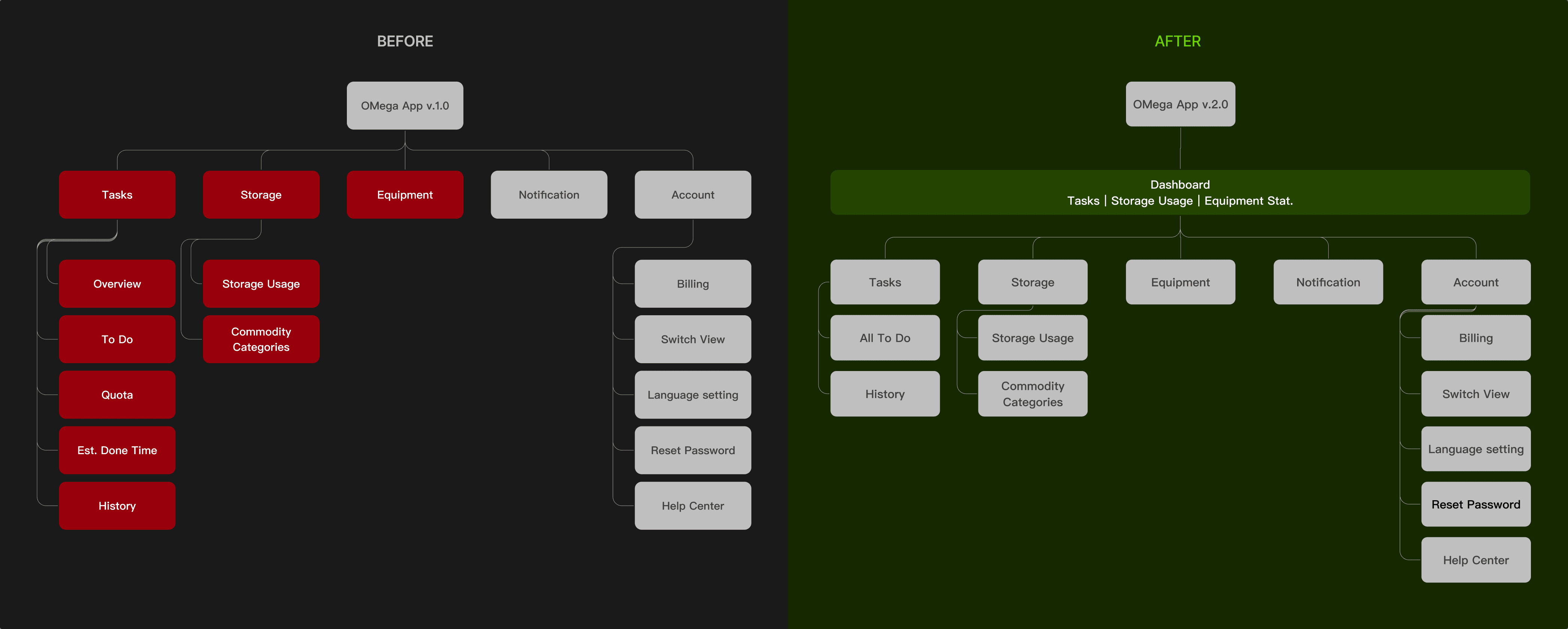

Before

Critical data scattered across 7 app pages

Staff had to navigate through 7 different screens to access essential warehouse information. This fragmented structure forced teams to constantly switch contexts, making it nearly impossible to get a complete operational picture

Challenge

How to balance eight stakeholder's data priorities while maximizing speed?

Each stakeholder level required distinct data depth and metrics across the system. Floor staff needed granular task data while executives needed aggregated insights.

High-level KPIs and trends

Real-time floor activity

Check real-time progress

Equipment status and alerts

System health and uptime

Delivery performances

Real-time progress tracking

Inventory delivery tracking

Key Decision 1

First, I unified all critical data by redesigning architecture

The new home screen consolidates the 7-screen workflow into a single 'Control Tower' view. Real-time metrics (left) and alert feeds (right) are now visible simultaneously, eliminating the need for context switching.

Key Decision 2

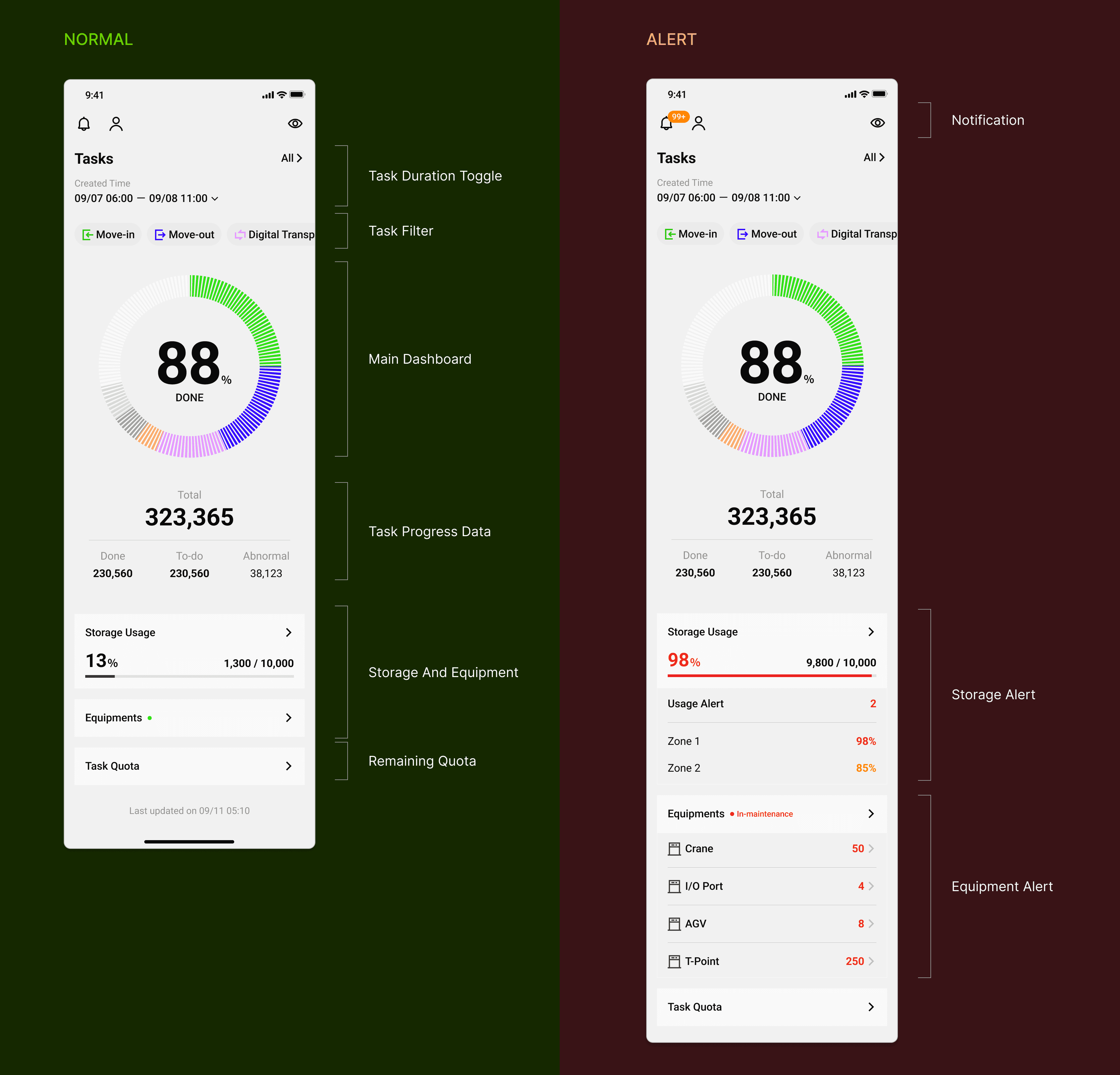

Second, I structured data hierarchy by urgency

Through interview, I found urgent information matters to all teams: alerts first, progress second, storage third, analytics last. Staff can now see task progress, storage capacity, and equipment alerts instantly.

The Design

Everything critical in one view, no more juggling

The new home screen consolidates the 7-screen workflow into a single 'Control Tower' view. Real-time metrics (left) and alert feeds (right) are now visible simultaneously, eliminating the need for context switching.

Impact

“The redesigned system ensures perfect information sync across all warehouse key users.”

Claire Hung

Product Manager, ALP

Key Feature 2

Alerts first, everything else follows

Before

Staff can't read dashboard from distances and in bright lighting

Mounted 5-10 meters above the warehouse floor, the existing dashboard's small text and low-contrast alerts became invisible in bright lighting conditions, preventing staff from catching critical issues.

Challenge

How to enable fast visibility across varying lighting?

Alert Visibility

Urgent alerts must stand out instantly

Font Legibility

Fonts large enough for quick reading

Data Hierarchy

Prioritize data by clear visual hierarchy

Varying Lighting Conditions

Visibility across all corners

Feature 1

Dynamic Layout surfaces alerts instantly — no scanning, no searching

Normal status fades to the background, but critical alerts snap to the top left the moment they appear—eliminating the scan-and-search delay when every second counts.

Feature 2

Dual-Mode Display adapts to complex lighting — from bright docks to dark aisles

Light Mode: Prevents washout in bright, sunlit loading docks.

Dark Mode: Reduces glare and eye strain in lower-light storage zones.

Key Learnings